New Innovative Method Using Patented Technology

Orono Spectral Solutions (OSS) has developed an innovative method that can quickly, accurately, and safely measure both volatile and non-volatile components of oil in water systems. Based on the ASTM D7575 method, the process involves capturing the oil in water using only one patented ClearShotTM extractor to measure both components, without the need for complex testing methods or equipment.

Ideally suited for any application that requires the measurement of volatile and non-volatile components, this methodology represents a dramatic leap forward over traditional methods in terms of testing capabilities, operator safety and cost savings. It is now possible to use the combined capabilities of the OSS ClearShot technology with FTIR units to measure various areas of the spectral range, knowing the results within minutes.

Challenges of Measuring Non-volatile and Volatile Oil in Water Components

OSS technology has significant benefits over traditional methods, which have been a challenge for several reasons. Measuring the non-volatile components typically involved using solvents in liquid / liquid extraction processes that are time consuming, require chemical fume hood protection and are costly. In addition, measuring the volatile components required the use of sophisticated and costly equipment operated by trained technical personnel. ClearShot Extraction technology eliminates both of these challenges.

About this Application Using ClearShot Technology

For this application, the non-volatile components are hydrocarbon materials with chain lengths of C16 and above. The volatile components are materials with chain lengths of C7 to C15. A key characteristic of the ClearShot extractor is that it allows for a total view of the FTIR spectrum, thus different oil peak regions can be utilized. This important aspect enables the measurement of both components in one region, and then after drying the extractor, measuring the non-volatile portion of the oil system in a different region.

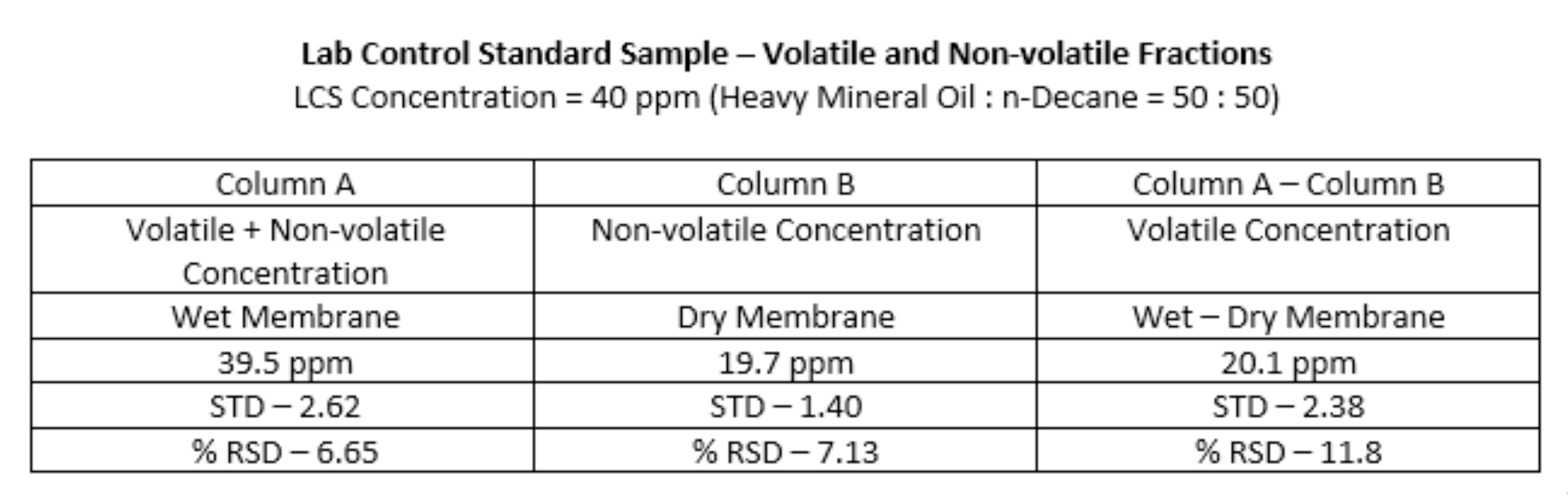

The chart below demonstrates the capabilities of the method to measure both components in a water system:

The following Q & A has been prepared to provide further insights into this innovative new approach:

Q: The OSS ClearShot method appears to measure volatile and non-volatile organics; is the method sufficient enough to ensure no variability in repeatability?

A: Yes. The OSS ClearShot method has been developed to handle C7 chain length materials and above by keeping the volatile components in the water matrix of the extractor membrane. If the procedure is followed and processed in the FTIR instrument in a timely manner (we have determined that the user has 10 minutes to process before the water matrix in the extractor membrane dissipates to the point that deviation would become a concern), then this should not be an operational issue in the field.

Q: Should the sample be homogenized?

A: The sample simply needs to be representative of the system, homogenous and processed in a timely manner. If there is a concern about the representativeness of the sample, it is possible to run replicate analyses of the given water matrix. This will provide the user with the understanding of the state of homogenization of the sample.

Q: Does the sample need to be cooled?

A: The sample does not need to be cooled for testing.

Q: Is there a practical oil concentration limit with this method?

A: No. For very high concentrations, there are two approaches that are discussed in the ASTM D7575 method to avoid such issues. The options include processing a smaller volume (e.g. 5ml vs 10m) and/or dilution of the sample followed by homogenization. The OSS method is based on mass loading, so adjusting either the sample size and/or dilution enables the user to measure any concentration level.

Q: The methods use IR wavelength peak height at two different points along the FTIR spectra. Does this impact the measurement?

A: These signals are directly correlated. Although the FTIR signal is larger at the 2920 region (which is why it is used for an optimum signal-to-noise scenario for the non-volatile test results), the signal peak in the bending mode, 1465 region, provides the same information content because it is directly correlated. The only difference here from a practical perspective is the reduction in signal-to-noise ratio. For the desired ppm detection levels, this signal-to-noise in the FTIR spectrum in this region is not an issue.