How Our ClearShot™ Technology Works

ClearShot Extraction Technology Accurately, Safely and Quickly Measures Extremely Low Non-volatile Residual Oil Concentrations in Critical Applications

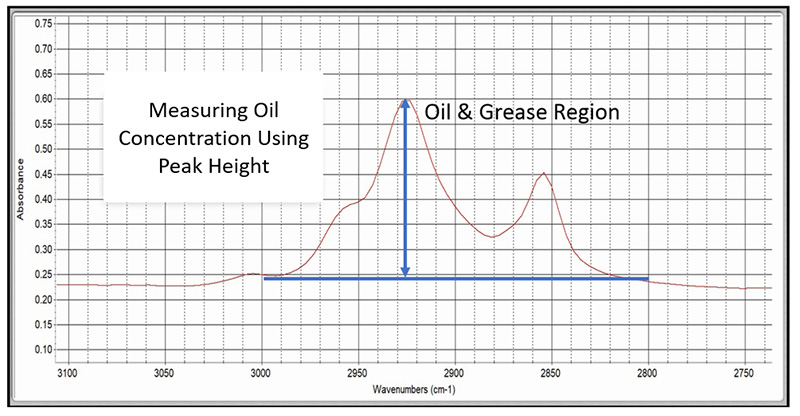

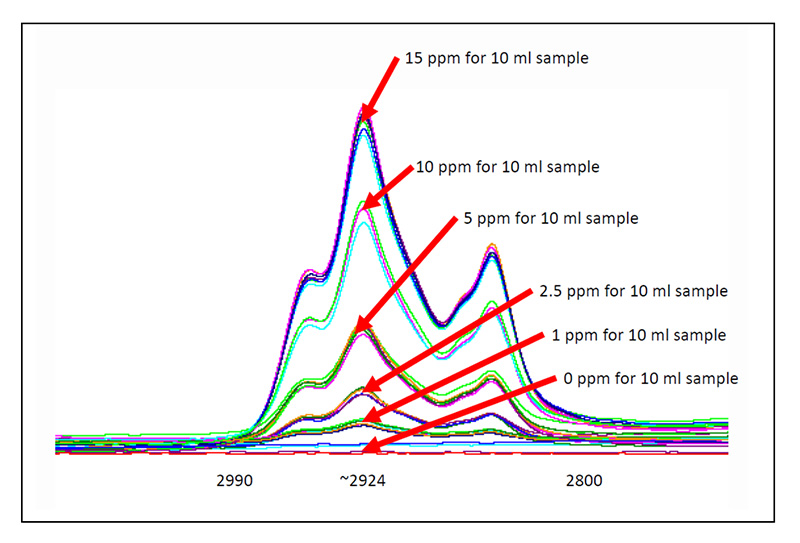

In a wide range of applications, oils are used as part of the process to achieve the desired end product functionality. Once that process has been completed, all oil must then be removed with the use of solvents. In these processes, any remaining oil can result in catastrophic disaster from significant equipment damage to loss of human life. Traditionally, it has been challenging to confirm that all oil has been properly removed. OSS has developed ClearShot systems, based on the specific characteristics of the oils and solvents, that can be used to quickly, accurately, precisely and cost effectively determine the concentration of any remaining oils in the cleaning solvents.